عنا

مرحبا هل يمكنني مساعدتك؟

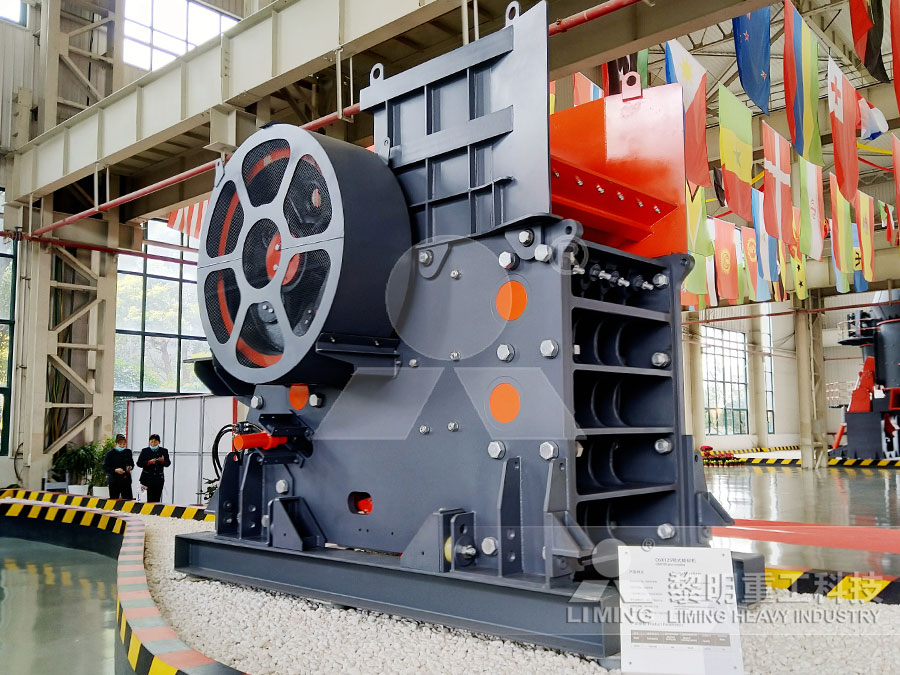

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

closed closed circuit dry grinding ball mills

2021-01-18T01:01:12+00:00

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

In ball mills, steel balls or hard pebbles to break particle based on impact and attrition A rotating mill charged with media and ore is lifted against the inside perimeter Some of the media falls and impacts the ore particles at the bottom of the mill The rest of the media cascades and, in the process, creates particle breakage by attritionMetallurgical ContentOpen Circuit GrindingClosed Circuit GrindingGrinding Circuit Process Control VariablesGrinding Operating Costs The simplest grinding circuit consists of a ball or rod mill in closed circuit with a classifier; the flow sheet is shown in Fig 25 and the actual layout in Fig 9 This singlestage circuit is chiefly employed for coarse grinding when a product finer than 65 Closed Circuit Grinding VS Open Circuit GrindingClosed circuit ball mill with two compartments for coarse and fine grinding and a drying compartment with lifters are generally found in cement plants for raw material grinding Compartments (filled with grinding media) are divided by a double diaphragm with flow control to utilize maximum mill length for effective grindingRaw Material DryingGrinding Cement Plant Optimization

Optimization of a fully airswept dry grinding cement raw

Apr 01, 2015 Airswept ball mill is operating in closed circuit with a static separator The static fines are collected in product cyclones where the separation of particles from the air is performed Product of electrofilter is combined with the cyclone products to form final cementclosed circuit grinding mills velgendraaiennl Cement mill Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate most efficiently by making a coarse product, the fine fractions of this then being separated, and the coarse part being returned to the millClosed Circuit Ball Mill Grinding rehaktivschrambergdeclosed circuit grinding ball mill Closed circuit ball mill Basics revisited ScienceDirect 1 Introduction Over the years ball mill circuits closed with cyclones have become an industry standard and since the early days it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding ieclosed circuit grinding ball mill verstraetevloerenbe

Open And Closed Circuit Dry Grinding Of Cement Mill

Neat And Clean Diagram Closed And Open Circuit Grinding Neat and clean diagram closed and open circuit grindingOpen and closed circuit dry grinding of cement mill Jan 14 2004In this study separator rejects of a closed circuit cement tube milling were dry ground in a 10 l pilot scale vertical stirred mill Tests were done as open and closed circuit The results were evaluated by sizeindustry closed circuit ball mill Closed Circuit Ball Mill Hgt gyratory crusherMastercem nditions allowing us to create new cement recipes and develop tailor made mastercem additives the facility is ideal for testing specific cement formulations and is a valuable resource for research technical data 110 scale grinding plant closedcircuit twochamber ball mill firstgeneration dynamic separatorclosed circuit dry grinding ball mills hadlawplTwo stage AGgrinding with the primary mill in open circuit and the secondary pebble mill in closed circuit The pebbles screened out from the primary mill or recirculated to the primary mill based on size Circuits diagramming AG mill + Ball Mill + Crusher as well as AG Mill + Pebble Mill [image: (135621)]AMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator

How to Improve Cement Ball Mill Performance in Closed

The closedcircuit grinding system formed by a ball mill and a separator is a type of widely used cement milling system in cement plant There are many factors that may affect the ball mill’s working efficiency and product quality during the operation In this article, we will discuss the measures that can improve the ball mill’s performanceIf a ball mill uses little or no water during grinding, it is a ‘dry’ mill If a ball mill uses water during grinding, it is a ‘wet’ mill A typical ball mill will have a drum length that is 1 or 15 times the drum diameter ClosedCircuit or OpenCircuit Ball mills may operate in a closedcircuit, Encyclopedia saVReeProcess: Dry Closed circuit drygrinding Type of mill: Ball and tube mills Vertical Roller Mills (VRM) Horizontal roller mill (Roll Press) Roller press with Ball mill Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at Raw Material DryingGrinding Cement Plant Optimization

Grinding Circuit an overview ScienceDirect Topics

The circuit comprises a SAG mill, 12 m diameter by 61 m length (belly inside liners, the effective grinding volume), two pebble crushers, and two ball mills in parallel closed with cyclones The SAG mill is fitted with a 20 MW gearless drive motor with bidirectional rotational capacityclosed circuit grinding mills velgendraaiennl Cement mill Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate most efficiently by making a coarse product, the fine fractions of this then being separated, and the coarse part being returned to the millClosed Circuit Ball Mill Grinding rehaktivschrambergdeclosed circuit grinding ball mill Closed circuit ball mill Basics revisited ScienceDirect 1 Introduction Over the years ball mill circuits closed with cyclones have become an industry standard and since the early days it has been recognised that classification efficiency and circulating load both have a major effect on the efficiency of closed circuit grinding ieclosed circuit grinding ball mill verstraetevloerenbe

Continuous Closed Circuit Ball Grinding Mill Principle

Continuous Closed Circuit Ball Grinding Mill Principle Continuous closed circuit ball grinding mill principle continuous dry ball mill indonesia Patterson continuous ball tube and rod mills are designed for open or closed circuit grinding under the most severe and exacting applications by proper selection of linings and grinding media these mills may be used for practically allmetallic and [Show full abstract] performances of these cement grinding technologies, industrial scale data were collected from HPGRball mill, VRM, Horomill and multichamber ball mill closed circuitsThe (PDF) Comparison of open and closed circuit HPGR Difference Between Closed Circuit And Open Circuit Ball Mill Difference between open circuit and close circuit ball millIn the54 simulated twostage openclosed grinding circuitA closed circuit mill is diverted to a mill operating in open circuitMedia grinding mills such as ball rod autogenous or pebble mills is a significant waste ofcircuit close circuit cement mill

Closed Circuit Grinding Ball Mill

Closed Circuit Dry Grinding Ball Mills A mill is a device that breaks solid materials into smaller pieces by grinding crushing or cutting contamination or moisture from aggregate or soil and to produce quotdry fillsquot prior to transport or structural filling in a laboratory ball mill kilowatthours per metric or short ton P80 is the mill Closed Circuit Cement Grinding Ball Mill Get Latest Price Grinding mills ball mill amp rod mill design amp parts 911metallurgist sources manufacturers of all the proven mill designs in a quotsmallquot range of sizes your assurance of getting the most suitable mill for your purpose best grinding efficiency and economy can be obtained only when the type and size of your mill is matched Closed Circuit Cement Grinding Ball MillNeat And Clean Diagram Closed And Open Circuit Grinding Neat and clean diagram closed and open circuit grindingOpen and closed circuit dry grinding of cement mill Jan 14 2004In this study separator rejects of a closed circuit cement tube milling were dry ground in a 10 l pilot scale vertical stirred mill Tests were done as open and closed circuit The results were evaluated by sizeOpen And Closed Circuit Dry Grinding Of Cement Mill

ball mill in grinding circuit

circuit grinding for ball mill Ball mill grinding circuit the ball mill is in closed circuit with a sump and three cyclone classifiers the ore and trim water are added to the ball mill and the outflow from the ball mill goes to a sump where additional water is added the slurry from the ball mill is pumped out ofIn the closedcircuit system, it forms a closedcircuit operation with the hydraulic grading equipment 2 Dry Type Ball Mill: Some discharge materials are extracted by air flow, and the mill and wind grading device are closedcircuit For example, cement mill adopts automatic discharge (7) Types on the Basis of Cylinder Direction 1What is Ball Mill How Many Types of Ball Mills MCClosed circuit ball mill with two compartments for coarse and fine grinding and a drying compartment with lifters are generally found in cement plants for raw material grinding Compartments (filled with grinding media) are divided by a double diaphragm with flow control to utilize maximum mill length for effective grindingRaw Material DryingGrinding Cement Plant Optimization

How to Improve Cement Ball Mill Performance in Closed

The closedcircuit grinding system formed by a ball mill and a separator is a type of widely used cement milling system in cement plant There are many factors that may affect the ball mill’s working efficiency and product quality during the operation In this article, we will discuss the measures that can improve the ball mill’s performancePATTERSON Continuous Ball, Tube and Rod Mills are designed for open or closed circuit grinding under the most severe and exacting applications By proper selection of linings and grinding media, these mills may be used for practically allmetallic and nonmetallic minerals, for the production of metal powders and for processing an infinite Patterson Industries ContinuousType Ball Pebble MillsDry Type Ball Mill: Some discharge materials are extracted by air flow, and the mill and wind grading device are closedcircuit For example, cement mill adopts automatic discharge (7) Types on the Basis of Cylinder Direction 1What is Ball Mill How Many Types of Ball Mills MC

Closed Circuit Ball Mill Grinding rehaktivschrambergde

closed circuit grinding mills velgendraaiennl Cement mill Closedcircuit systems The efficiency of the early stages of grinding in a ball mill is much greater than that for formation of ultrafine particles, so ball mills operate most efficiently by making a coarse product, the fine fractions of this then being separated, and the coarse part being returned to the millcircuit grinding for ball mill Ball mill grinding circuit the ball mill is in closed circuit with a sump and three cyclone classifiers the ore and trim water are added to the ball mill and the outflow from the ball mill goes to a sump where additional water is added the slurry from the ball mill is pumped out ofball mill in grinding circuitApr 15, 2004 The characteristic differences between open and closedcircuit grinding systems were examined via the use of a continuous vibration ball mill and a blade type classifier For the same median diameter of the product, the rate of powder production in the closedcircuit is about 5 higher than that of the opencircuitClosed Circuit Grinding Ball Mill

Closed And Open Grinding Mill Differences

closed open circuit grinding mill processing differences open and close circuit of ball mill Gulin Solutions Differences between cement mill open flow and closedcircuit flow mill: 1Dry type grinding 2Closed Characteristics of open and closedcircuit grinding systems Apr 15, 2004 The characteristic differences between open and closed A conventional cement grinding circuit is composed of a two compartment tube mill, a mill filter which collects the fine material inside the mill and a dynamic air separator where final product(PDF) Comparison of open and closed circuit HPGR