عنا

مرحبا هل يمكنني مساعدتك؟

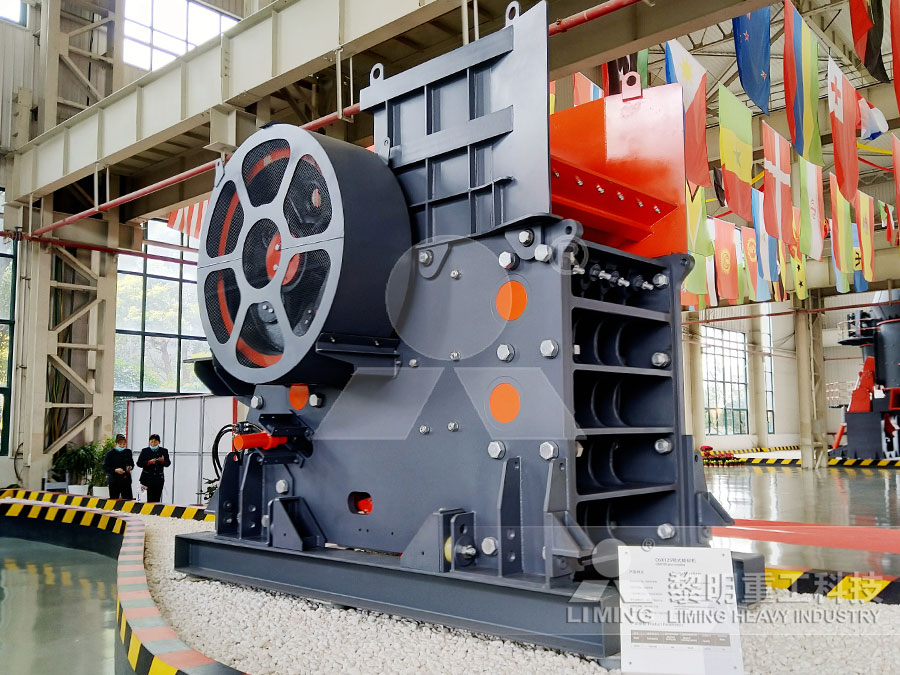

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

uranium surface mining flowchart

2021-08-11T12:08:59+00:00

Uranium Surface Mining Flowchart

Uranium Surface Mining Flowchart Cameco U101 Mining Mining uranium involves the same processes used to mine many other metals Depending on the deposit, uranium is mined in one of three ways Deposits close to the surface can be recovered using the open pit mining methodUranium mining is the process of extraction of uranium ore from the ground The worldwide production of uranium in 2019 amounted to 53,656 tonnes Kazakhstan, Canada, and Australia were the top three producers and together account for 68% of world uranium production Other important uranium producing countries in excess of 1,000 tonnes per year were Namibia, Niger, Russia, Uzbekistan and Uranium mining WikipediaAfter locating uranium deposits and obtaining appropriate permits, a company will begin to mine There are a few ways to extract uranium from the ground: openpit mining, underground mining and insitu recovery Mining methods depend on the type of deposit, whether it's suspended in water and the geography of the areaHow Uranium Mining Works HowStuffWorks

cameco uranium mill process flow chart

uranium surface mining flowchart view flow chart uranium open pit mining, Uranium Surface Mining Flowchart Uranium Mining55 Кб Uranium mining Most uranium mining utilizes conventional open pit or underground methods depending on the location and quality of the oreIn this case uranium is released from rock into the ground water using a solvent and then pumped to the surface [Chat Uranium is a naturallyoccurring radioactive element that has been mined and used for its chemical properties for more than a thousand years It is now primarily used as fuel for nuclear reactors that make electricity Uranium can be recovered in two ways: by conventional mining of the rock (ore), or by using strong chemicals to dissolve uranium from the rock that is still in the ground and Radioactive Waste From Uranium Mining and Milling Uranium mining methods Uranium ore is extracted from the ground in one of three ways: open pit mining, underground mining or insitu recovery Openpit mining When uranium ore is found near the surface, generally less than 100 metres deep, it is typically extracted by the openpit mining method Underground miningCanadian Nuclear Association

New uranium mines: no simple answers Local azdailysun

Oct 15, 2017 The mines have a much different uranium target than those on the Navajo Nation: large, underground vertical pipes of highgrade uranium ore that measure 200 to method of mining the uranium on the Moser tract was the in situ leaching process actually in use, and that this method did not result in substantial destruction of the land's surface"I United States Steel Corporation, therefore, could continue to mine the uranium as the lessee of the mineral estate ownerOil, Gas, and Minerals SMU Scholaruranium as a byproduct from the crude black acid (30% phosphoric acid) obtained from the leaching of phosphate for fertilizers 2 Generalized Proc ess Flow Diagram Conventional Milling Uranium ore is recovered by either open pit (for ore deposits close to the surface of the earth) or underground mining The ore is blended, crushed, and ground3rd ed, Vol XXIII, 1983, p 504

Uranium Mining Uranium Mines Nuclear Power

Nuclear Fuel Cycle Source: Nuclear Regulatory Commission from US License: CC BY 20 Uranium mining and milling is the starting process for all nuclear fuel cyclesIn this process uranium ore is extracted from the Earth’s crust similarly as for mining of copper, zinc, and other metals Uranium is often found with copper, phosphates, and other minerals; thus, it is often a coproduct of Uranium mining is the process of extraction of uranium ore from the ground The worldwide production of uranium in 2019 amounted to 53,656 tonnes Kazakhstan, Canada, and Australia were the top three producers and together account for 68% of world uranium production Other important uranium producing countries in excess of 1,000 tonnes per year were Namibia, Niger, Russia, Uzbekistan and Uranium mining WikipediaJan 01, 2016 61 Introduction 611 Historic mining for pigment and radium (to 1939) Uranium minerals were known, without a detailed knowledge of their elemental composition, at least from 1565 in the Saxonian Ore Mountains (Erzgebirge) in Germany and Bohemia (modern Czech Republic) (Dahlkamp, 1993)Uranium was identified in minerals from this region by Martin Klaproth, although he Uranium mining (open cut and underground) and milling

cameco uranium mill process flow chart

uranium surface mining flowchart view flow chart uranium open pit mining, Uranium Surface Mining Flowchart Uranium Mining55 Кб Uranium mining Most uranium mining utilizes conventional open pit or underground methods depending on the location and quality of the oreIn this case uranium is released from rock into the ground water using a solvent and then pumped to the surface [Chat Because most uranium mining occurred in the western United States, and this Agency effort coincided with a Colorado Plateau initiative in the Environmental Protection Agency’s (EPA’s) Region 8 office in Denver, Colorado, the initial database compilation efforts were focused thereUranium Location Database CompilationUranium mining methods Uranium ore is extracted from the ground in one of three ways: open pit mining, underground mining or insitu recovery Openpit mining When uranium ore is found near the surface, generally less than 100 metres deep, it is typically extracted by the openpit mining method Underground miningCanadian Nuclear Association

New uranium mines: no simple answers Local azdailysun

Oct 15, 2017 The mines have a much different uranium target than those on the Navajo Nation: large, underground vertical pipes of highgrade uranium ore that measure 200 to Mar 26, 2012 understanding the Saskatchewan mining industry, with a focus on the Potash and Uranium industries The objective is to provide accurate and relevant information to assist manufacturers inHow to successfully access the Mining Supply ChainWheeler River is the largest undeveloped uranium project in the infrastructure rich eastern portion of the Athabasca Basin region, in northern Saskatchewan, noted the firm It has combined indicated mineral resources of 1321 million pounds U3O8 (1,809,000 tonnes at an average grade of 33% U3O8), plus combined inferred mineral resources of 30 Denison changes design for insitu uranium project

A topdown assessment of energy, water and land use in

Nov 01, 2013 Uranium is a secondary product at Olympic Dam, where surface mining techniques are also used and waste rock haulage and energy consumption are reported only for the mine as a whole Mudd and Diesendorf (2008) studied the infrastructure at Olympic Dam associated with each product; he recommended that 20% of waste rock haulage and energy uranium as a byproduct from the crude black acid (30% phosphoric acid) obtained from the leaching of phosphate for fertilizers 2 Generalized Proc ess Flow Diagram Conventional Milling Uranium ore is recovered by either open pit (for ore deposits close to the surface of the earth) or underground mining The ore is blended, crushed, and ground3rd ed, Vol XXIII, 1983, p 504Open Pit Mining Open pit mining, also known as strip mining, is the removal of surficial soils and uneconomic rock to get at the ore below Ore grades are normally less than 05% This is type of mining is only possible if the uranium ore is near the surface (normally less than 400 ft)Uranium — How Is It Mined?

Uranium Mining Overview World Nuclear Association

Uranium Mining Overview (Updated September 2020) In the last 60 years uranium has become one of the world’s most important energy minerals It is mined and concentrated similarly to many other metals While uranium is used almost entirely for making electricity, a small proportion is used for the important task of producing medical isotopesProcess Of Mining Uranium Flow Chart uranium mill processing flow chart cameco uranium mill process flow chart The Wild Hog39s Instablog Seeking Alpha Jun 29, 2010, Take for example the 2 oil rig explosions in the Gulf, or the WV mine explosions, Cameco is major supplier of uranium processing services required to produce, The chartpares Cameco Cameco Uranium Mill Process Flow Charturanium surface mining flowchart view flow chart uranium open pit mining, Uranium Surface Mining Flowchart Uranium Mining55 Кб Uranium mining Most uranium mining utilizes conventional open pit or underground methods depending on the location and quality of the oreIn this case uranium is released from rock into the ground water using a solvent and then pumped to the surface [Chat cameco uranium mill process flow chart

Ecological amendment of uranium mine tailings using native

Naturally occurring uranium consists of three isotopes with mass number, 238, 235, and 234 Uranium238 constitutes 9928% of the natural uranium, which is in equilibrium with 234 U (00058%) Uranium235, the progenitor of the actinium series is present in the amount of 071% (Engelbrecht, 2020) In the uranium ore, which is not subjected to Wheeler River is the largest undeveloped uranium project in the infrastructure rich eastern portion of the Athabasca Basin region, in northern Saskatchewan, noted the firm It has combined indicated mineral resources of 1321 million pounds U3O8 (1,809,000 tonnes at an average grade of 33% U3O8), plus combined inferred mineral resources of 30 Denison changes design for insitu uranium project Underground Mining Methods Flow Chart potash, and bedded uranium ores,) results in subsidence of the surface, causing sink holes to appear(PDF) Underground mining Methods ResearchGate

extraction process flow chart in mines Bacula Konferencja

extraction process flow chart in mines Copper mining amp extraction process flow chartthis flowchart made of machinery icons explains or expresses in simple but clear terms the step of the copper mining and copper extraction process starting from either openpit or underground mining and using a different relevant treatment method for oxide or sulphide copper mineral ore having a quick look Mar 26, 2012 understanding the Saskatchewan mining industry, with a focus on the Potash and Uranium industries The objective is to provide accurate and relevant information to assist manufacturers inHow to successfully access the Mining Supply ChainUranium is extracted through two primary techniques: surface or underground mining In Situ Recovery (ISR) Mining is a safe, proven method that accounts for about 30% of world uranium production, and is the primary mining technique used by Uranium OneClean Energy Uranium One

Uranium Mining Wyoming State Geological Survey

Mining is the removal of material from the earth's interior for the purpose of extracting a commodity of interest (uranium, gold, aluminum, etc) After mining, uranium ore is processed into yellowcake, a type of uranium concentrate powder obtained from leach solutionsThe native groundwater continues in this cycle until uranium extraction is complete In situ recovery has several significant advantages over conventional mining First, the environmental impact is minimal, as there is little surface disturbance and the affected water is restored at the conclusion of miningInSitu Uranium Mining Process UrEnergyJan 27, 2016 Back in December, several media outlets reported on a study released by the US Geological Service (USGS) that found 60 million pounds of uranium deposits in South Texas and estimated that another 200 million pounds of ore remains undiscovered Those in favor of nuclear power may see the recent USGS study as good news, and while motives behind nuclear may be well Newly Discovered Uranium Sparks Mining Interest Despite