عنا

مرحبا هل يمكنني مساعدتك؟

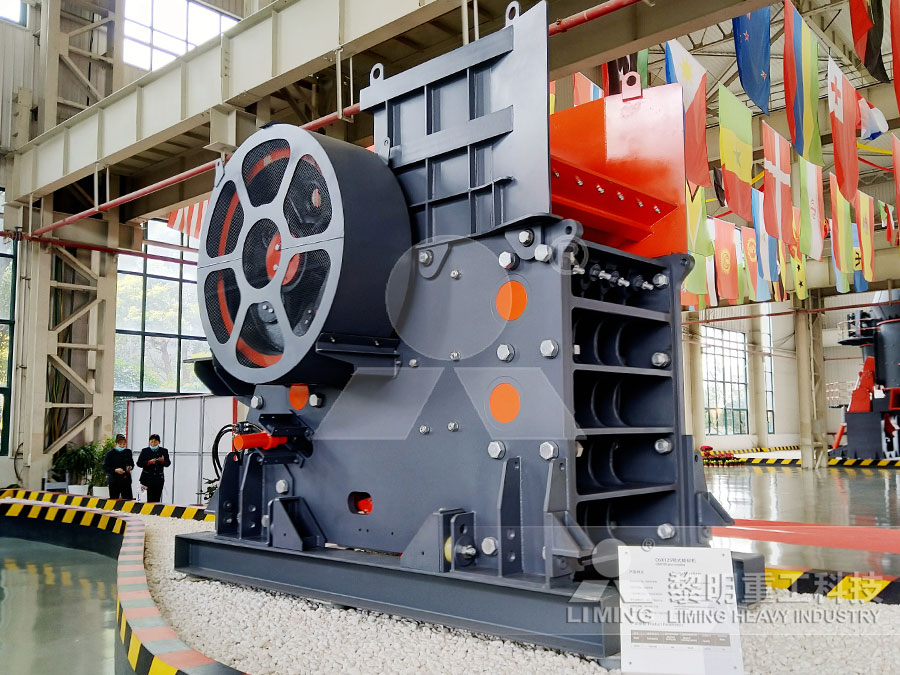

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

what is the procedure to opperate a ball mill of cement

2019-04-12T22:04:13+00:00

procedure to operate a ball mill of cement

cement ball mill operation procedure Holi King What is the procedure to operate a ball mill of cement mill operation procedure grinding mill machine ball mill ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation ProcedureBecause the roller press and the ball mill are two separate circulate system, the whole cement grinding process is easy to operate and control The grinding efficiency of the system is also enhanced because qualified fine powers from the roller press don’t need to be ground again by the ball millBall Mill Roller Press for Cement Grinding Process

Cement making process Great Wall Corporation

The hot clinker is used to preheat the air for burning the coal, and the cooled clinker is stored ready for use Cement milling The clinker is finely ground with about 5% gypsum in another ball mill, producing cement (The gypsum regulates the early setting characteristic of cement)cement ball mill operation procedure Holi King What is the procedure to operate a ball mill of cement mill operation procedure grinding mill machine ball mill ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous procedure to operate a ball mill of cementMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available As such you will find it is designed and constructed according to heavy duty specifications It is designed along sound engineering principles Ball Mill Maintenance Installation Procedure

Optimization of Cement Grinding Operation in Ball Mills

Jul 18, 2016 Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills Ball mills have been the traditional method of comminution in the mineral processing industries and continue to operate with old generation The hot clinker is used to preheat the air for burning the coal, and the cooled clinker is stored ready for use Cement milling The clinker is finely ground with about 5% gypsum in another ball mill, producing cement (The gypsum regulates the early setting characteristic of cement)Cement making process Great Wall CorporationApproach to High Temperature of Cement Ball Mill In the operation of cement ball mill, the stop can cause a large temperature difference on the mill body, resulting in significant thermal stress and thermal deformation, and sometimes even cause mechanical damage of the ball mill, such as the geometric deformation of the linerStarting the thermal deformation after the stop grinding can Approach to High Temperature of Cement Ball Mill

What is the ball milling process? Crushers, Sand making

Apr 28, 2020 The ball mill is widely used in the production of new construction materials, cement, refractory materials, nonferrous metals and glass ceramics The ball mill has the characteristics of high production efficiency, environmental protection, low grinding cost, and continuous productionJul 20, 2020 P ortland cement is by far the most common type of cement in general use around the world This articles looks at the cement manufacturing process in 4 steps Step 1: Mining The first step of Cement manufacturing process is to quarry the principal raw Cement manufacturing process: Stepbystep guide CCE l A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Ball mill Wikipedia

A ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating about its axis TOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect TopicsJan 26, 2021 Although there are several mill types capable of grinding clinker, the most commonly used cement mill process is the ball mill Ball mills are highly effective grinding systems which subject the raw material to relatively low heat and pressure levels They consist of large diameter, rotating cylinders or drums driven by electric motorsWhat is a Cement Mill? (with pictures)

What Is The Process Of Cement Grinding Crusher Mills

Cement crushing plant,process line,mill operation,grinding Ball mill is the most popular cement grinding machine used for grinding cement into powder in process line Ball mill is an excellent tool to select mine or grind a Dec 22, 2020 The cement fineness is a determining factor in product quality Estimating this variable in realtime can be extremely useful to maintain the desired characteristics of the product during the cement grinding process, which will also allow a significant increase in the system energy efficiency This paper describes the design and implementation of aSoft Sensor for Online Cement Fineness Predicting in Ball process control in industrial ball mills remains an open problem motivating future research activities and comprehensive studies [2, 19, 26, 27, 48] We shall conclude this section by mentioning (PDF) Grinding in Ball Mills: Modeling and Process Control

Ball Mill Maintenance Installation Procedure

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill Jul 18, 2016 Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with ball mills Ball mills have been the traditional method of comminution in the mineral processing industries and continue to operate with old generation Optimization of Cement Grinding Operation in Ball Mills The use of ball mills in cement grinding is due to several factors, among which are relatively simple design and high processing rate However, these machines have certain limitations as well It is known that only 2 to 20% of the energy is consumed by the grinding proper, while the rest is expanded on overcoming friction, on vibrations and is Cement Grinding in Ball Mills and Vortex Layer Devices

Cement making process Great Wall Corporation

The hot clinker is used to preheat the air for burning the coal, and the cooled clinker is stored ready for use Cement milling The clinker is finely ground with about 5% gypsum in another ball mill, producing cement (The gypsum regulates the early setting characteristic of cement)Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum rotates approximately once every couple of secondsThe cement millApplication of Soft Constrained MPC to a Cement Mill Circuit The cement manufacturing process is illustrated in Fig 1 The final cement mill circuit consists of a ball mill and a separator are fed to the ball mill along with recycle material from create a piecewise quadratic penalty function in such a Get Pricefunction of ball mill in cement manufacturing process

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at 2800 blaine I chamber linersUse of the diaphragm is almost universal with ball mills in the cement and rock products industries because of the many dry grinding operations in this field It is optional on ball mills in the mining industry, but not recommended for rod mills Diaphragms are standard equipment for Preliminator, Ballpeb and Compeb mills Mill Discharge HeadsGrinding Mills 911MetallurgistGrinding Technology And Mill Operations Flsmidth Ball mills and vertical roller mills are used for many grinding applications in cement production raw meal grinding coal and pet coke and finish cement grinding improving the competences of the team plays a key role in the optimal utilisation of the grinding installation in your cement plant the operators and process Complete Process Of Cement Ball Mill Grinding

Soft Sensor for Online Cement Fineness Predicting in Ball

Dec 22, 2020 The cement fineness is a determining factor in product quality Estimating this variable in realtime can be extremely useful to maintain the desired characteristics of the product during the cement grinding process, which will also allow a significant increase in the system energy efficiency This paper describes the design and implementation of aCement crushing plant,process line,mill operation,grinding Ball mill is the most popular cement grinding machine used for grinding cement into powder in process line Ball mill is an excellent tool to select mine or grind a What Is The Process Of Cement Grinding Crusher Mills what is the procedure to operate a ball mill of cement what is finish mill of a cement process Mining Quarry This series of ball mill is suitable for ore dressing, chemical, coal, cement and refractory sectors to operate fine grinding Bearingtype drive ball mill is a Finishing: Anodizing, Plating, Powder Coating, Getcoading cement mill process manganeseorestonecrusherco

Ball Mill In Cement Plant Specification

Ball Mill In Cement Plant Specification vollendamnl cement ball mill specification chauffagenannibe The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on The best ball mills, however, enable you to achieve the desired product quality quickly and e ciently, with minimum energy expenditure That’s what the ball mill is designed to do – with the added benefit of high flexibility You decide whether to operate the mill in open or closed circuit, with or without a pregrinderBall mill Superior cement quality, More fl exibility