عنا

مرحبا هل يمكنني مساعدتك؟

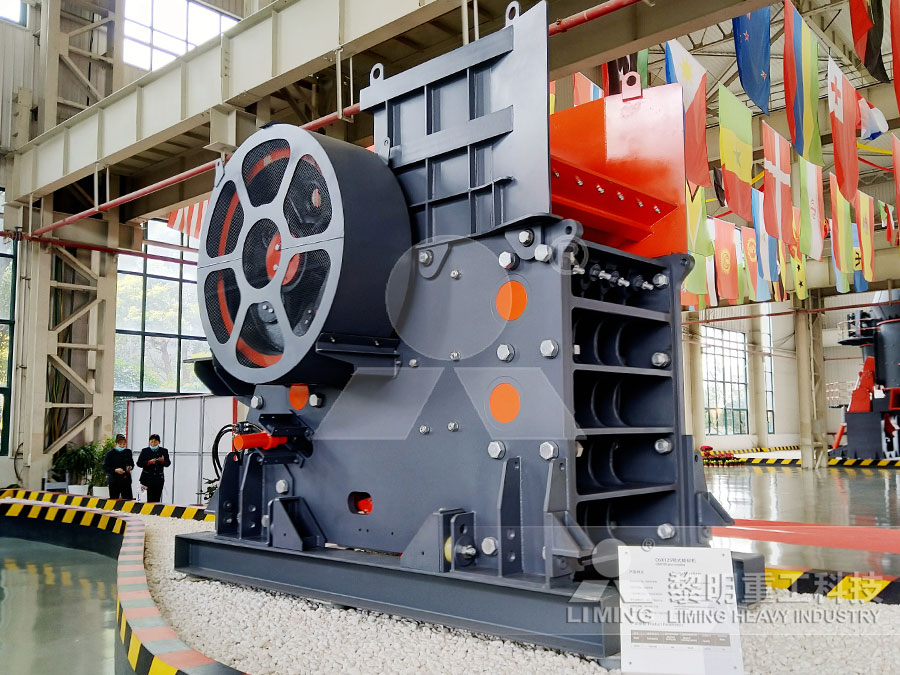

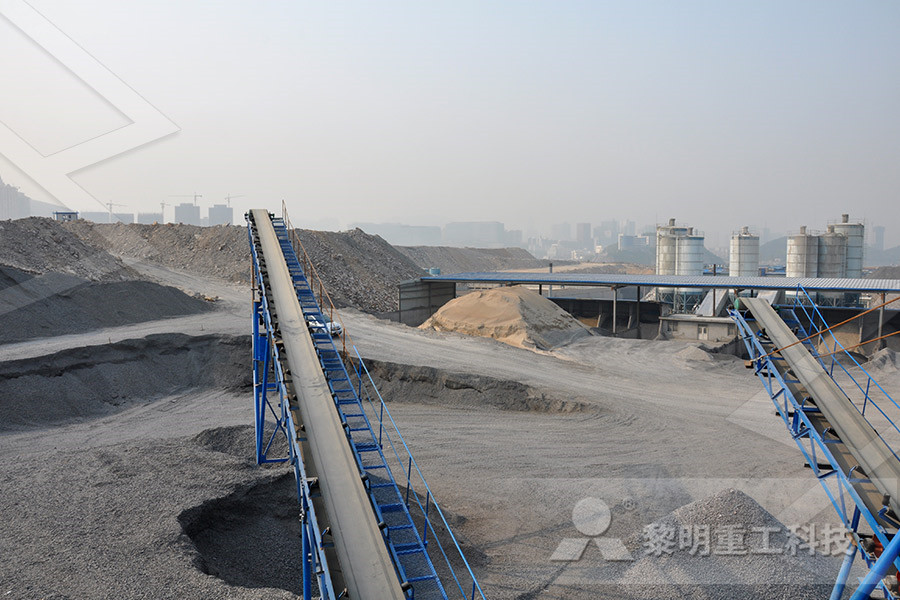

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

jaw crusher responses

2020-06-10T17:06:33+00:00

Cause Analysis and Problems Solving of Jaw Crusher

Dec 10, 2019 Jaw crusher has a large crushing force and fast running speed Under the action of the huge impact and crushing stress, it withstands longterm and periodic contact fatigue load and is prone to fatigue crack Therefore, fatigue spalling is also one of the causes of wearWhat is a Jaw Crusher? A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V) The movable jaw compresses material against the fixed jaw, crushing the material to the desired size The material exits the jaw through the bottom of the crusher otherwise, known as the discharge openingWhat is a Jaw Crusher? TelsmithDec 25, 2014 The jaw crushers can be seen in the mining and disposal industry where large rocks need to be crushed into smaller pieces for further use There are different jaw crushers on the market, but all of them are designed and are consisted of fixed and moveable partsThe Working Principle Of A Jaw Crusher Editors Top

Jaw Crushers McLanahan

A Jaw Crusher uses compressive force for breaking material This mechanical pressure is achieved by the crusher's two jaws dies, one of which is stationary and the other is movable These two vertical manganese jaw dies create a Vshaped cavity called the crushing chamber, where the top of the crushing chamber is larger than the bottomRocksizer Jaw Crushers RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well shaped product and reduced and even wear on Jaw Crushers Parker PlantMay 10, 2019 Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications, where some other primary crushing solutions simply do not fit Types of Jaw Crushers Jaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

how a jaw crusher works and what it is used for

A Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plateWhat is a Jaw Crusher? A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V) The movable jaw compresses material against the fixed jaw, crushing the material to the desired size The material exits the jaw through the bottom of the crusher What is a Jaw Crusher? TelsmithDec 25, 2014 The jaw crushers can be seen in the mining and disposal industry where large rocks need to be crushed into smaller pieces for further use There are different jaw crushers on the market, but all of them are designed and are consisted of fixed and moveable partsThe Working Principle Of A Jaw Crusher Editors Top

Jaw Crushers MEKA Crushing Screening Plants

Jaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and secondary types of these crushersJun 28, 2017 Expert Witness Response Jaw crushers are used to crush different types of material, such as hard rocks, ore, building rubble, and glass Jaw crushers have one fixed and one movable crushing jaw that supports the crushing platesMan Injured by Defective Toggle Plate on Jaw CrusherRocksizer Jaw Crushers RockSizer primary stage jaw crushers feature the upthrust toggle action which is also common to the StoneSizer range Developed by Parker, this gives a slight downward movement to the swing jaw that promotes a forced feed and therefore increased output while at the same time minimising any rubbing action resulting in a well shaped product and reduced and even wear on Jaw Crushers Parker Plant

Laboratory Jaw Crusher 911Metallurgist

Description A Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding Principle of operation of this crusher The Model 100 mm X 130 mm 911MPEJC100 Jaw Crusher is used by laboratories and Dec 05, 2011 The Vanguard Plus series from KPIJCI represents the very latest in jaw crusher technology Engineered to be the highest capacity jaw crusher on the market, youJaw Crusher Animation YouTubeJan 07, 2017 Would love to be able to make my own crushed stone and gravel I have screened piles of rock while excavating my house site I am trying to build a jaw cruHomemade Jaw Crusher YouTube

Jaw Crusher Trio® CT Series Primary Weir

Trio® CT series jaw crushers combine a robust design with a steep nip angle and an optimised toggle This results in a crusher which offers a more aggressive bite and reliable operation, with lifecycle improvements of its mechanical and hydraulic parts The CT series can also be fitted with a hydraulic toggle relief system as requiredThe gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesJaw Crusher an overview ScienceDirect TopicsJaw crusher is a trusted for its high quality and good manufacturing Jaw Crusher which is widely applied to crush high hardness, mid hardness and soft rocks and ores such as slag, construction materials, marble, etc It is widely used as primary and secondary crushing equipment to crush Industrial Crusher Industrial Mobile Jaw Crusher

Jaipuria Enterprises Manufacturer of Jaw Crusher Belt

Our incorporation, “Jaipuria Enterprises” is struggling in this industry for several years and these years of efforts come in an outstanding way that we are gratifying the huge clients’ baseOur association is a Private Limited Company based venture We have settled our main head office at Kannur, Bengaluru, KarnatakaSince 2018, we are matching up with the neverending necessities of May 10, 2019 Due to their smaller physical size, jaw crushers are also ideal for tight spaces, such as underground mining and mobile crushing applications, where some other primary crushing solutions simply do not fit Types of Jaw Crushers Jaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher How Does a Jaw Crusher Work Jaw Crusher Kemper EquipmentA Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on how a jaw crusher works and what it is used for

Introduction of jaw crusher yxmineengineering

Introduction of jaw crusher Introduction Jaw crushers are mainly used as coarse crushers and medium crushers in mining, building materials, infrastructure and other sectors Jun 28, 2017 Expert Witness Response Jaw crushers are used to crush different types of material, such as hard rocks, ore, building rubble, and glass Jaw crushers have one fixed and one movable crushing Man Injured by Defective Toggle Plate on Jaw CrusherJaw crushers reduce large rocks or ore by means of compression Mechanical pressure is applied using the crusher’s two jaws; one is fixed while the other reciprocates There are also primary and Jaw Crushers MEKA Crushing Screening Plants

Jaw Crusher an overview ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber This crusher produces less fines but the aggregates have a more elongated Jaw crushers are operated to produce a size reduction ratio between 4:1 and 9:1 Gyratory crushers can produce size reduction ratios over a somewhat larger range of 3:1 to 10:1 The primary operating variable available on a crusher is the set and on jaw TECHNICAL NOTES 5 CRUSHERS Mineral TechDec 05, 2011 The Vanguard Plus series from KPIJCI represents the very latest in jaw crusher technology Engineered to be the highest capacity jaw crusher Jaw Crusher Animation YouTube