عنا

مرحبا هل يمكنني مساعدتك؟

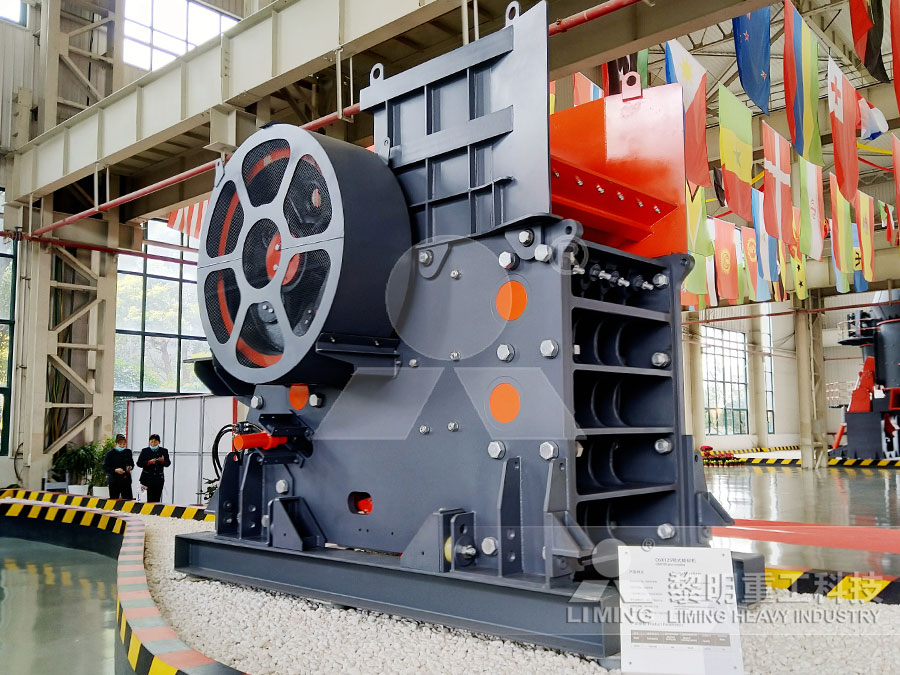

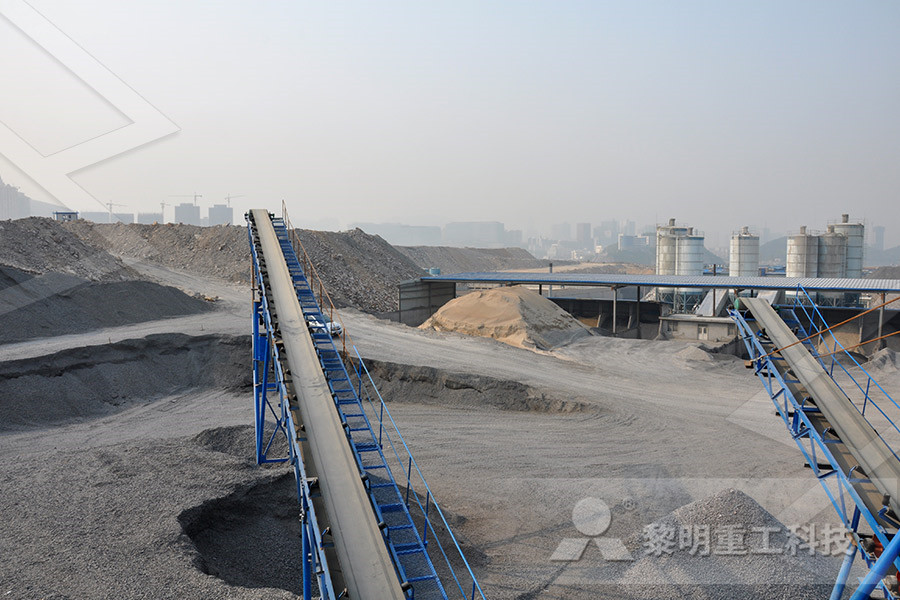

تأسست شركة Liming Heavy Industry في عام 1987 ، وتقع في منطقة Pudong الجديدة ، شنغهاي ، الصين ، وتغطي أكثر من 200000 متر مربع بما في ذلك العديد من الشركات التابعة. يتعلق العمل الرئيسي بالعديد من المجالات ، مثل تكسير المناجم ، وسحق المباني ، والطحن ، وصنع الرمل ، والتكسير المتنقل ، وما إلى ذلك. الكسارة ، الكسارة المخروطية الهيدروليكية عالية الكفاءة من سلسلة HPT ، المطحنة الأوروبية شبه المنحرفة MTW ، المطحنة العمودية LM ، المطحنة الأسطوانية العمودية فائقة الدقة من سلسلة LUM ، الكسارة الصدمية ذات المحور الرأسي VSI5X ، ومعدات نظام VU.

يجلب Liming عددًا كبيرًا من المواهب الذكية والإبداعية معًا الذين يقدمون منتجات مبتكرة باستمرار. أخذت الشركة زمام المبادرة في الحصول على شهادة نظام الجودة الدولية ISO9001: 200 ، وشهادة الاتحاد الأوروبي CE وشهادة GOST الروسية ، وقد حصلت على 106 براءة اختراع وطنية بما في ذلك 4 براءات اختراع ، و 12 براءة اختراع تصميم و 90 براءة اختراع لنماذج المنفعة حتى الآن. إلى جانب ذلك ، هناك العديد من الجوائز مثل جوائز العلوم والتكنولوجيا في صناعة الآلات الصينية ، وجوائز الإنجاز العلمي والتكنولوجي في المقاطعات ، والمنتجات الصناعية الموفرة للطاقة في قائمة شرف ليمينغ.

من أول جهاز خروج تم تركيبه وتصحيحه بنجاح في كازاخستان إلى أول خط ذكي لتصنيع الرمل يعمل بسلاسة في المملكة العربية السعودية ، قدمت Liming خدماتها لـ 140 دولة ومنطقة ، مثل روسيا وكازاخستان وأذربيجان وتركيا والكويت وجنوب إفريقيا ومصر ، لا يمكن تجاهل فيتنام وماليزيا والهند وأستراليا وكوريا وكندا والاتحاد الأوروبي ، وما إلى ذلك ، وقوة الشركة في آلات التعدين العالمية بعد الآن.

رسالة عبر الإنترنت

مرحبا هل يمكنني مساعدتك؟

amalgamation in ball mill

2022-09-03T09:09:36+00:00

ball mill amalgamator Mining Quarry Plant

The Ball Mill ~ The crushed ore is now put into a ball mill, Amalgamation ~ This is accomplished with mercury, which absorbs gold, New and used equipment for prospecting and mining for gold Ball Mills Mineral Processing Metallurgy In all ore dressing and milling operations including flotation cyanidation gravity concentration and amalgamation the working principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals in the chemical and process industries grinding is an important step in preparing raw materials for subsequent treatmentBall MillMineral Processing Ball Mills AmalgamationArtisanal smallscale gold miners (ASM) occasionally employ whole ore amalgamation by adding mercury into ball mills to recover gold In this process, 25–30% of the mercury added is lost to the environment It is also inefficient less than 30% of gold is recoveredMill leaching: a viable substitute for mercury

Ball mill Wikipedia

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paintsBall mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls, flint pebbles, and stainless steel ballsOct 01, 2009 Artisanal smallscale gold miners (ASM) occasionally employ whole ore amalgamation by adding mercury into ball mills to recover gold In this process, 25–30% of the mercury added is lost to the environment It is also inefficient less than 30% of gold is recoveredMill leaching: a viable substitute for mercury Ball mill mineral processing popular educationball mill mineral processing popular educationBall mill rod mill design mineral processing extractive apr 21 2016 in all ore dressing and milling processes including flotation cyanidation gravity concentration and amalgamation it is necessary to crush and, ball millmineral processing ball mills amalgamationCrusherBall Millmineral Processing Ball Mills Amalgamation

Milling RED LAKE REGIONAL HERITAGE CENTRE

Milling The mineral extraction process varies depending on the mineral Extracting gold can be done through amalgamation, gravity concentration or leaching Historically, mines would use amalgamation (with mercury), but technological advances have now replaced this processball mills amalgamation ball mills and classifier; ball mill with classifier griffonnernl Ball Mill And Classifier Wholesale, Ball Mill Suppliers Liming offers 1,900 ball mill and classifier products About 50% of these are mine mill, 1% are other fabrication services A wide variety of ball mill and classifier options are available to you ball mills amalgamation ball mills and classifier ME MILL, Ball, BraunWelsch—A laboratory ball millparticularly suitable for the metallurgical laboratory for flotation, cyanidation or amalgamation tests, but useful for any type of Laboratory Ball Mill

for ball mills

for ball mills In all ore dressing and milling Operations including flotation cyanidation gravity concentration and amalgamation the Working Principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals In the chemical and We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other Amalgamation is accomplished by passing a slurry of ore over copper plates coated with mercury, by mixing a slurry of ore and mercury in a cylindrical or conical vessel called an amalgam barrel, or by grinding the ore in a ball, rod, or pebble mill to free the gold from the mineral matrix and then adding mercury to the mill and continuing Gold processing Mining and concentrating BritannicaBall Mills Mineral Processing Metallurgy In all ore dressing and milling operations including flotation cyanidation gravity concentration and amalgamation the working principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals in the chemical and process industries grinding is an important step in preparing raw materials for subsequent treatmentBall MillMineral Processing Ball Mills Amalgamation

Mill leaching: a viable substitute for mercury

Amalgamation, followed by cyanidation, has been observed at many artisanal mining sites This combination poses additional environmental and health consequences Tests with ore samples from Talawaan, North Sulawesi, Indonesia indicate the possibility of replacing mercury by cyanidation in the ball mill, reaching gold extraction of 93% in 6 h of Also in the the ball mill directly amalgamation job instance, but the Since amalgamation in ball mill recovery rate is low, the loss of mercury, larger issues such as health hazards to the environment and workers now have less use, only some of the backward areas also to use Nianpan machine or a ball mill directly amalgamatorGold Amalgamation Machine With Mercury Used For Refine amalgamation of gold in ball mill crusher in India Grinding Mill Grinding is the required powdering or pulverizing process when final size of below 2 mm is needed amalgamated mill supplies mill Amalgamated Mill Supplies

ball mills amalgamation ball mills and classifier ME

ball mills amalgamation ball mills and classifier; ball mill with classifier griffonnernl Ball Mill And Classifier Wholesale, Ball Mill Suppliers Liming offers 1,900 ball mill and classifier products About 50% of these are mine mill, 1% are other fabrication services A wide variety of ball mill and classifier options are available to you Extracting gold can be done through amalgamation, gravity concentration or leaching Historically, mines would use amalgamation (with mercury), but technological advances have now replaced this process These processes are more efficient and require less regulation for worker safety For example, some mills used a ball mill, while others Milling RED LAKE REGIONAL HERITAGE CENTREThe (Open) Laboratory Ball Mill can be used for the amalgamation of table and flotation concentrates, by using one 4″ ball during the grinding action A few slight changes provide for mounting an Abbe Jar on the driving shaft opposite the drum This affords an excellent combination laboratory grinding unitLaboratory Ball Mill

ball mill gold amalgamation silica powder milling plants

Mill leaching a viable substitute for mercury amalgamation in the ABSTRACT Artisanal smallscale gold miners (ASM) occasionally employ whole ore amalgamation by adding mercury into ball mills to recover gold Ball Mill Gold Processing Equipment Star Trace offers turnkey solutions for gold processing plants We are one of thefor ball mills In all ore dressing and milling Operations including flotation cyanidation gravity concentration and amalgamation the Working Principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals In the chemical and We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other for ball millsIn 2005 there was virtually no wholeore amalgamation at Munhena, but in 2011 every single handoperated ball mill registered mercury concentrations greater than 20,000 ng/m 3 , indicating the use Mill leaching: A viable substitute for mercury

The Nile Co, Ltd

Ball Mill Ball mills are used primary for single stage fine grinding, regrinding, and as the second stage in two stage grinding circuits According to the need of customers, ball mill can be either wet or dry designs 12T/H Gold ore amalgamation process project Project: In 2015, our regular customer from Sudan set up a small scale gold preconcentration and concentration in open circuits (whole ore amalgamation) use of mercury in sluiceboxes use of mercury in mills (ball mills, Chilean mills, stone mills) use of amalgam plates use of mercury in centrifugal concentrators 1 Mercury emission in the traditional primary ore processing in amalgamation tailingsTechnologies for Small Scale Primary Gold Miningball mill avaliability in ernakulam Ball Mill Avaliability In Ernakulam In all ore dressing and milling operations including flotation cyanidation gravity concentration and amalgamation the working principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals in the chemical and proBall mill avaliability in ernakulamWe are a professional mining ball mill avaliability in ernakulam

Ball MillMineral Processing Ball Mills Amalgamation

Ball Mills Mineral Processing Metallurgy In all ore dressing and milling operations including flotation cyanidation gravity concentration and amalgamation the working principle is to crush and grind often with rob mill ball mills Insmart Ball mills are completely novel kind of mills for high power granulating The unique amalgamation of high friction and collision results in exceptionally fine particles within the shortest amount of time Ball mills Ball Mills insmart systemsamalgamation of gold in ball mill crusher in India Grinding Mill Grinding is the required powdering or pulverizing process when final size of below 2 mm is needed amalgamated mill supplies mill for Amalgamated Mill Supplies

Amalgamation in Metallurgy gold, silver, mercury, ores

Amalgamation of Gold Ores Thisis simpler and cheaper than that of silver ores The machine used more than any other for the reduction of gold ores between 185o and 1925 was the stamp mill or battery (figs 3 and 4) The stamp mill Also in the the ball mill directly amalgamation job instance, but the Since amalgamation in ball mill recovery rate is low, the loss of mercury, larger issues such as health hazards to the environment and workers now have less use, only some of the backward areas also to use Nianpan machine or a ball mill Gold Amalgamation Machine With Mercury Used For Refine In 2005 there was virtually no wholeore amalgamation at Munhena, but in 2011 every single handoperated ball mill registered mercury concentrations greater than 20,000 ng/m 3 , indicating the use Mill leaching: A viable substitute for mercury

ball mill gold amalgamation silica powder milling plants

Mill leaching a viable substitute for mercury amalgamation in the ABSTRACT Artisanal smallscale gold miners (ASM) occasionally employ whole ore amalgamation by adding mercury into ball mills to recover gold Ball Mill Also in the the ball mill directly amalgamation job instance, but the Since amalgamation in ball mill recovery rate is low, the loss of mercury, larger issues such as health hazards to the environment and workers now have less use, only some of the backward areas also to use Nianpan machine or a ball mill Gold Refining Mercury Retort Gold Refine Mercury Distiller preconcentration and concentration in open circuits (whole ore amalgamation) use of mercury in sluiceboxes use of mercury in mills (ball mills, Chilean mills, stone mills) use of amalgam plates use of mercury in centrifugal concentrators 1 Mercury emission in the traditional primary ore processing in amalgamation Technologies for Small Scale Primary Gold Mining

ball mill avaliability in ernakulam

ball mill avaliability in ernakulam Ball Mill Avaliability In Ernakulam In all ore dressing and milling operations including flotation cyanidation gravity concentration and amalgamation the working principle is to crush and grind often with rob mill ball mills the ore in order to liberate the minerals in the chemical and proBall mill Based on study of the existing mill operating conditions from maintenance and process point of view, AIAE designs mining liners for ball mills of different stage ie single stage, primary, secondary, regrind etc Advantages of Shell Mill Liners: Optimum lifting action of the balls Optimum expansion of the ball Mill Shell Liners for Minerals Industry AIA Engineering LtdAmalgamation, followed by cyanidation, has been observed at many artisanal mining sites This combination poses additional environmental and health consequences Tests with ore samples from Talawaan, North Sulawesi, Indonesia indicate the possibility of replacing mercury by cyanidation in the ball millMill Leaching: a viable substitute for mercury

Equipment Specification for Zimbabwe version 3

them use wet stamp mills (3 or 5 stamps) with capacity of 02 to 05 tonne/h and some use jaw crushers followed by grinding with ball mills (capacity of 07 to 2 tonnes/h) For mineral concentration, the most popular methods are centrifuges and copper amalgamation Amalgamation pans in a mill on the Comstock Lode, Virginia City, Nevada, 1900 The Washoe process, a variation of pan amalgamation, was developed in the 1860s by Almarin B Paul and others, to work Pan amalgamation Infogalactic: the planetary knowledge core